AFT is a leading manufacturer of precision parts, assemblies & market-ready products

For more than 30 years, we’ve been a trusted supplier for high-tech vertical markets including medical, semiconductor, networking, telecom, oil & gas, transportation, defense, aerospace, green energy and more.

Leverage our experience

AFT customers appreciate sound advice and consulting for their design and manufacturing projects. Decades of experience is the advantage our customers realize for lower costs and quicker speed to market. Our customer care team keeps projects on schedule.

Manufacturing Innovation

Our experience and innovative approach to project delivery enables us to understand your unique needs and adopt a manufacturing plan that is cost effective and efficient. We guide your design and manufacturing process to ensure successful delivery of quality products.

Robust Partnerships

An extensive base of partnerships in Silicon Valley, and beyond, allow us to consistently deliver projects with complex requirements. In addition to our full-service facility in Hayward, California, we work with boutique partners for plating, clean-room assembly and high quantity output.

Innovative approach & commitment to superior service

Our comprehensive data collection and measurement process allows us to react quickly to our customer’s requests. Projects begin with a thorough discovery and road-mapping process facilitated by enterprise resource planning tools. By investing in the latest software and production planning, we’ve incorporated estimating, RFQs, work orders, purchasing, MRP, stock control, costing, scheduling, reporting, shop floor data capture, quality control, MES, delivery notes, cash management, invoicing and accounting.

Quality Assurance

- First Article Process

- Quality Review & Plan Development

- Process Capability & Monitoring

- Continuous Improvement Program

- Optical Scanning Technology

- Portable Faro Arm-CMM

- ISO 9001.2015 Registered

Engineering Services

- Process Engineering / NPI Model

- DFM Capabilities / ECO Coordination

- File Transfer & Processing

- Tool / Fixture Design

- CAD / CAM

- Mastercam & Geopath

- Fabriwin / AP100

- Solid Works

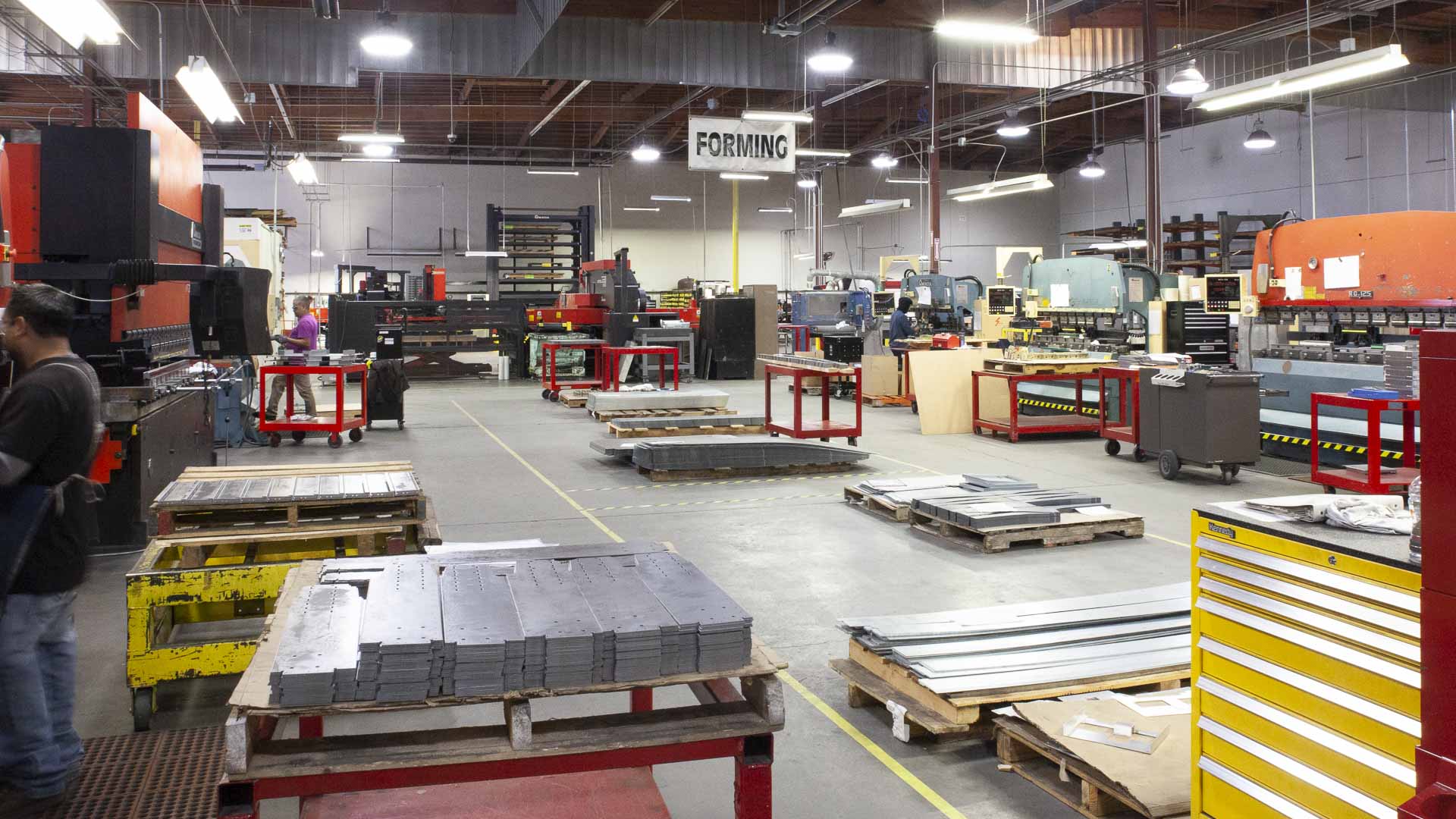

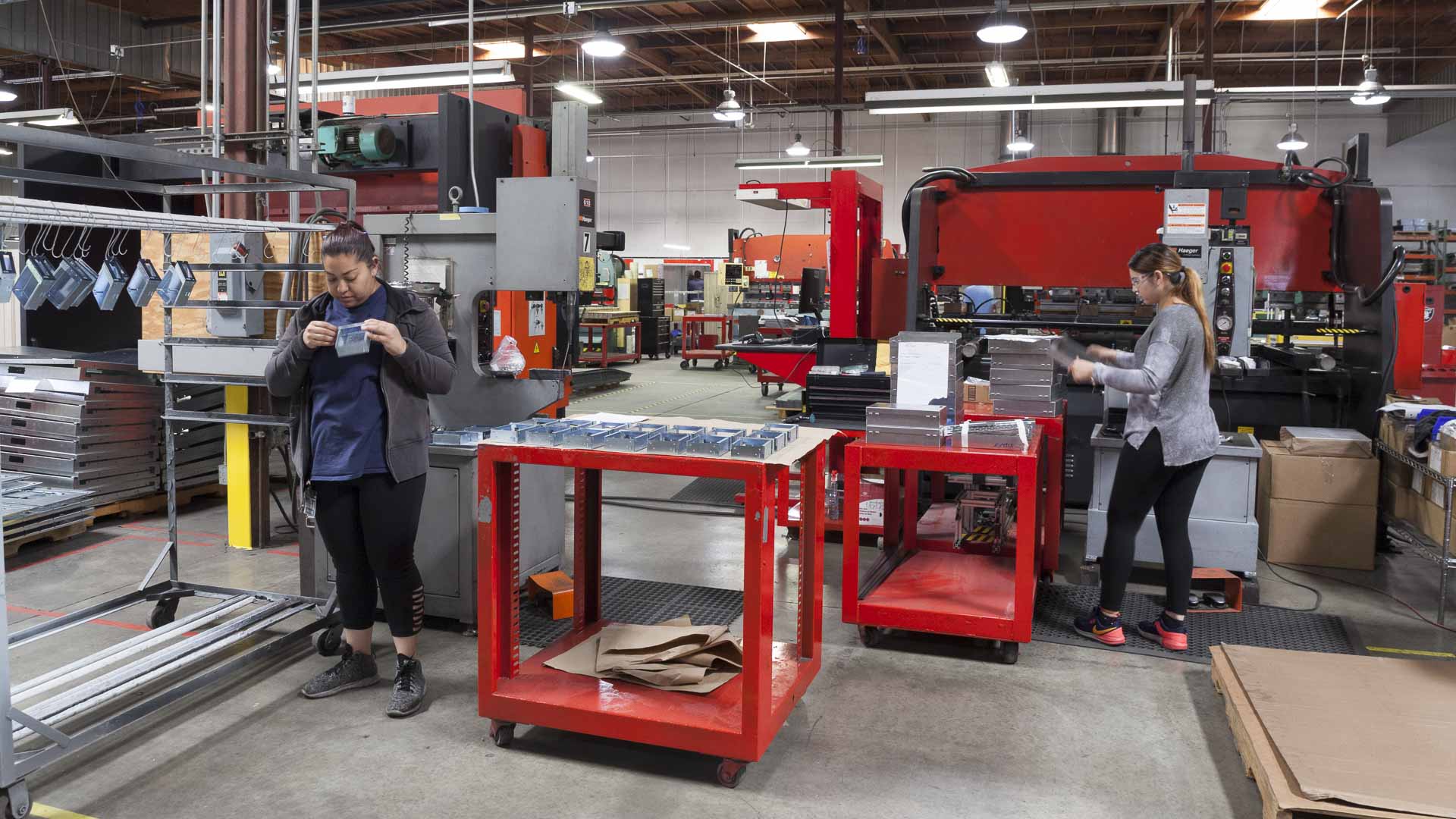

Manufacturing Processes

Our 50,000sf facility is home to skilled trades people and the most modern process and equipment. Operational efficiency, automation and flexibility allow for quick turn around and consistent precision.